Introducing New Next-Generation 12-Station Tablet Dissolution Testing Instruments PTWS 1230 and PTWS D630

Introducing New Next-Generation 12-Station Tablet Dissolution Testing Instruments PTWS 1230 and PTWS D630

We are pleased to announce the upcoming launch of its next-generation PTWS tablet dissolution testing instruments. They are available for order now and will begin shipping in the first quarter of 2026. Designed with a modern graphical user interface, advanced user management features, and a fully integrated audit trail, the new systems set a new benchmark in usability and compliance.

The introduction of our next-generation tablet dissolution tester marks an important milestone in our over forty-five-year history. Designed with user requirements in mind, these systems reflect our commitment to delivering user-oriented, robust, and sustainable solutions with long-term value to our customers.

Pharma Test CEO Björn Fähler

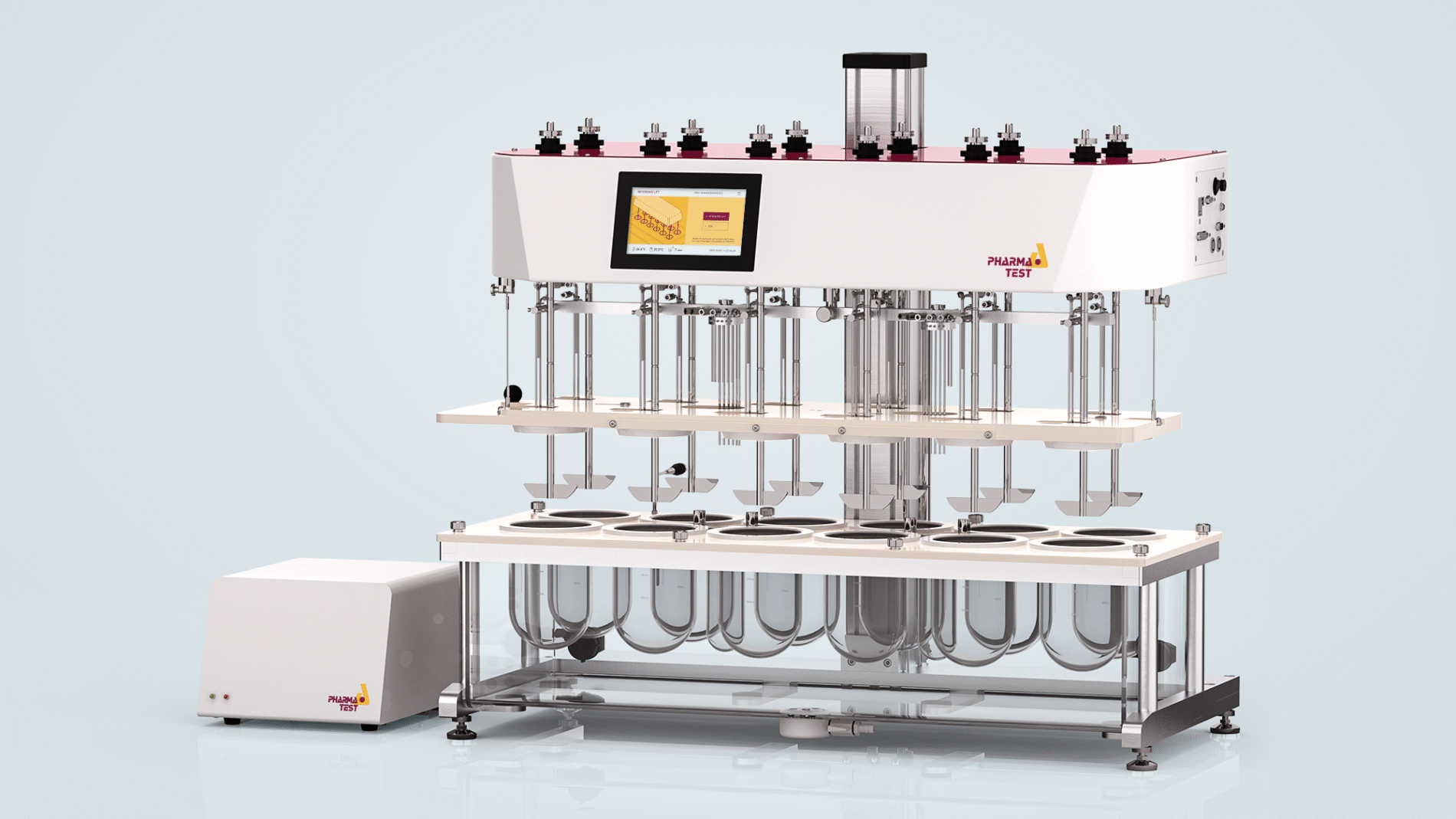

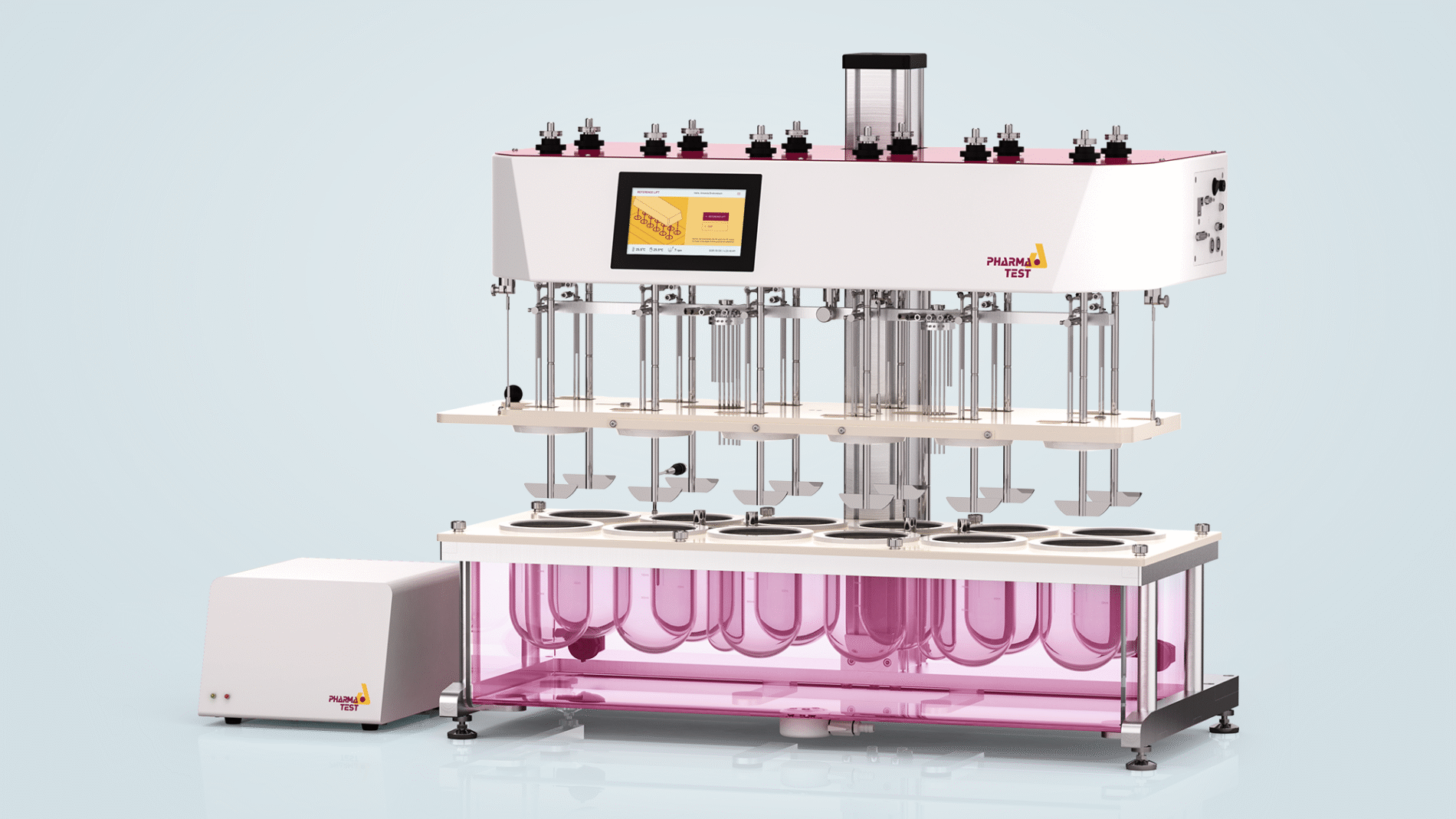

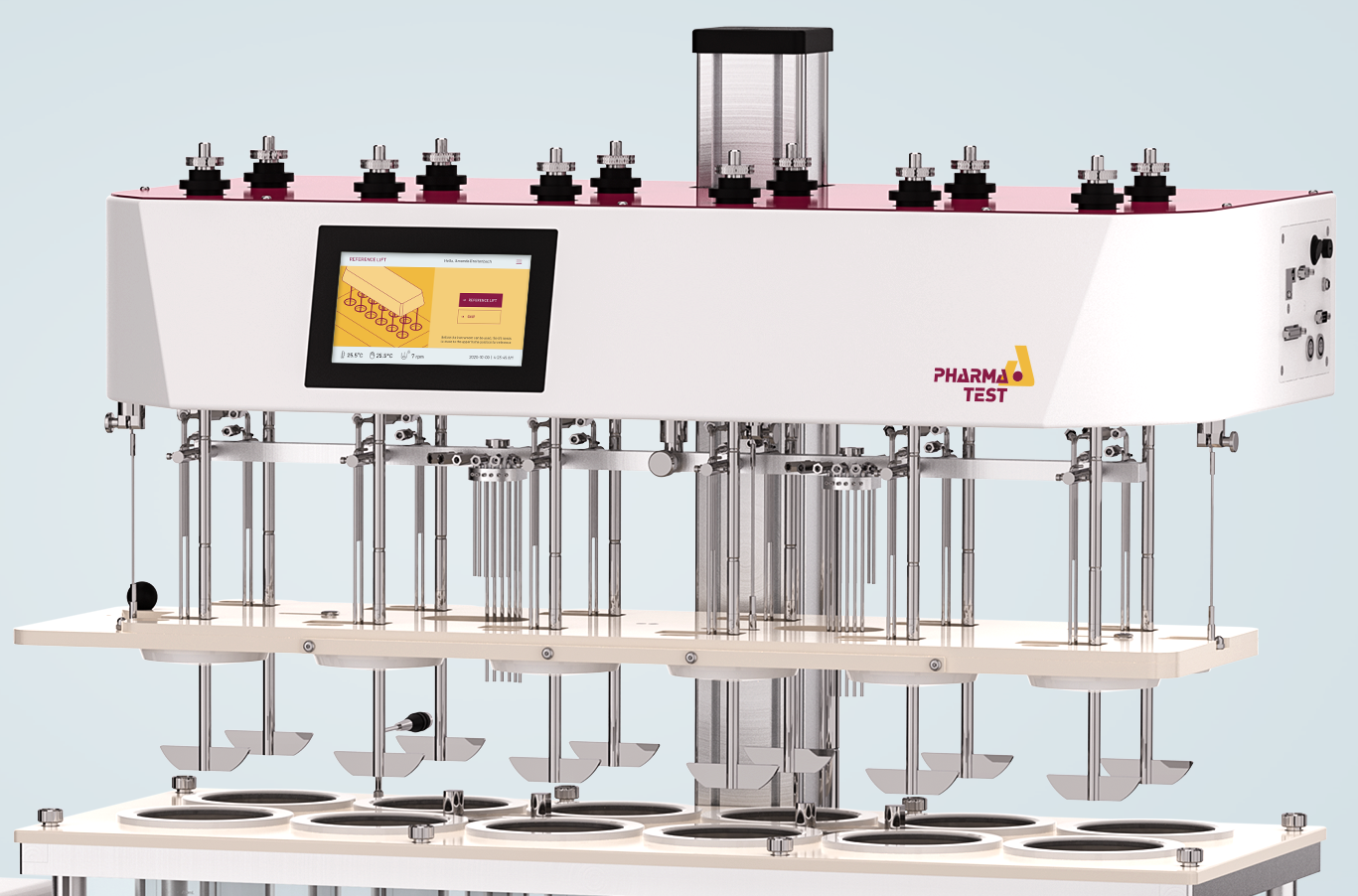

New PTWS 1230 12-station tablet dissolution testing instrument – with water bath preservative ALGEX Magenta (on the right / bottom)

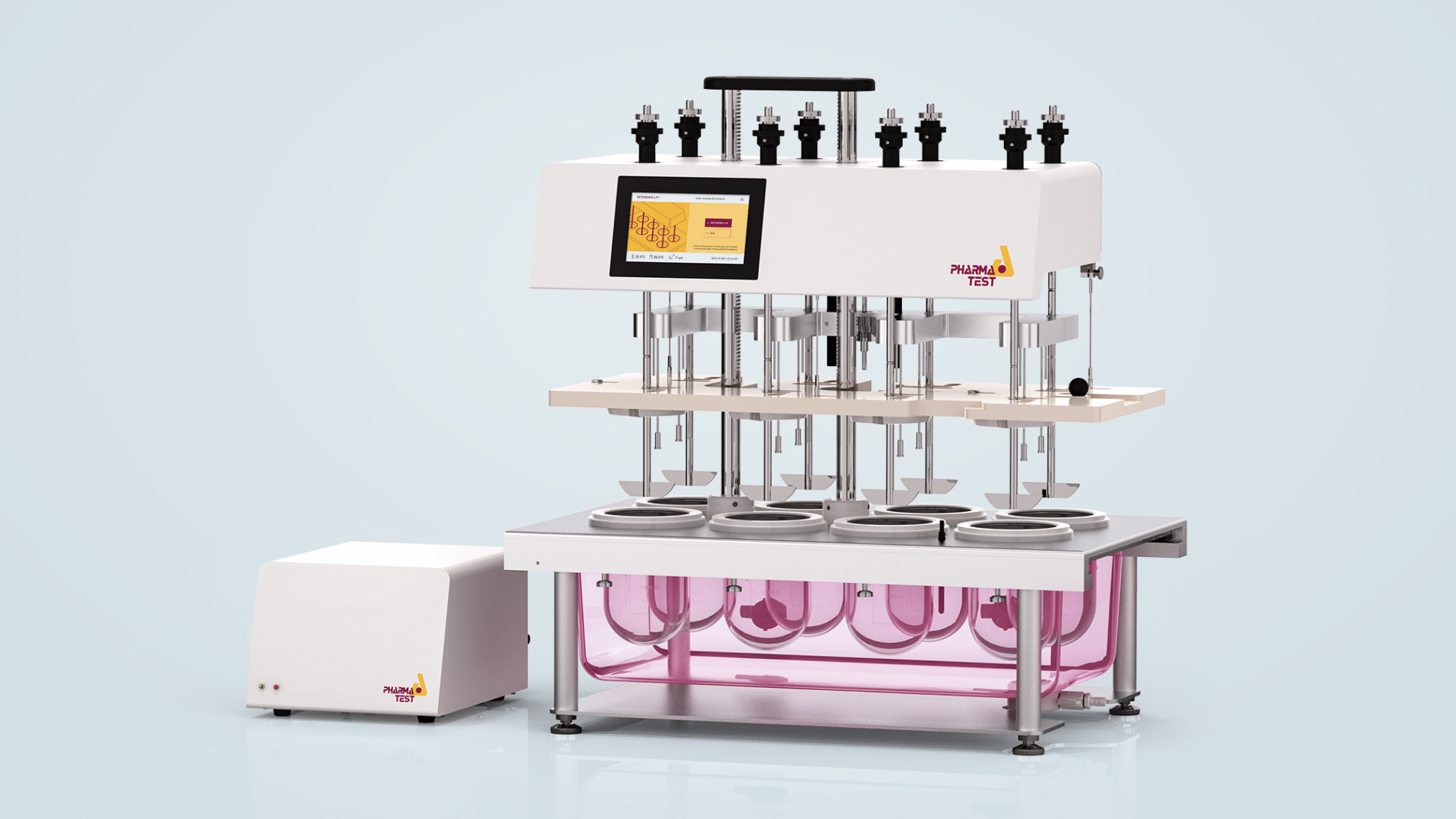

New PTWS 830 8-station tablet dissolution testing instrument – with water bath preservative ALGEX Magenta (on the right / bottom)

Available Models

Three new models of tablet dissolution testing instruments are available to order now and will begin shipping in the first quarter of 2026:

- PTWS 830: Eight-station dissolution tester

- PTWS 1230: Twelve-station dissolution tester

- PTWS D630: “Dual drive” six-plus-six station dissolution tester

Advanced Touch Screen User Interface

Touch Screen Operation and User Management

The instruments are equipped with a wide 7-inch color touch screen, designed to enhance usability. The new user interface incorporates rich graphical elements, smooth animations, and clear explanatory texts to guide users through every function. The flexible user management system allows for the inclusion of an unlimited number of users, ensuring secure and customized access. Additionally, the system supports an unlimited number of test methods, providing adaptability for a wide range of laboratory needs.

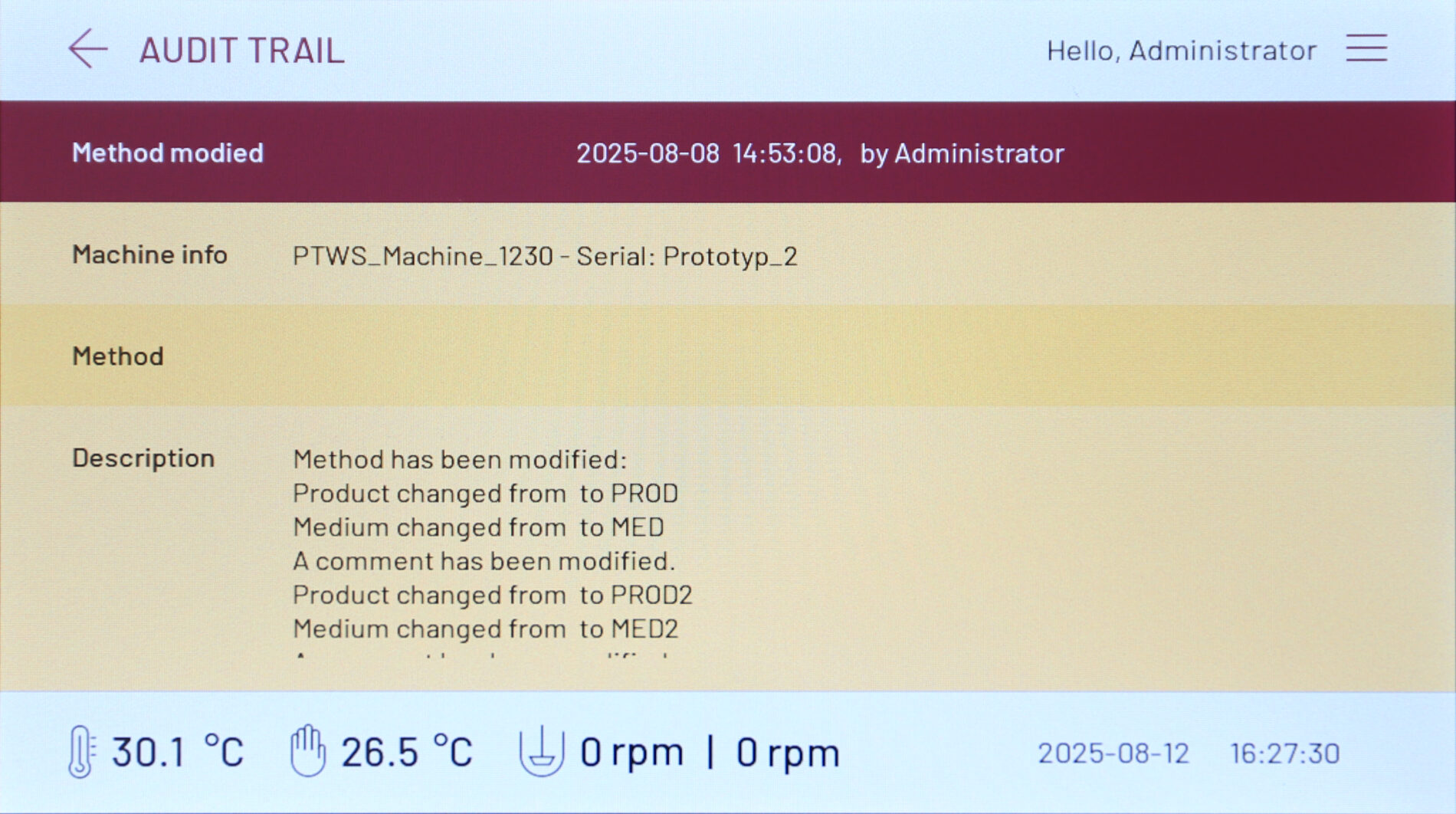

Compliance and Audit Trail Features

The audit trail system records all events and changes within the instrument, providing a detailed account with both before and after information, fulfilling the regulatory requirements of 21 CFR Part 11. The audit trail can be filtered using criteria such as date & time, user, method and type of event.

Highly Responsive Touch Screen Operation

All instrument interactions are carried out via a capacitive touchscreen interface, engineered to remain highly responsive even when operated with laboratory gloves. This design not only enhances user convenience but also supports strict hygiene standards in laboratory environments.

PTWS 1230 and PTWS D630 Instrument Features

Both PTWS 1230 and PTWS D630 instruments arrive fully configured and ready for immediate use. Each package includes a complete set of USP vessels, stirrer shafts, and USP apparatus 2 paddles, ensuring compliance with regulatory standards and facilitating efficient laboratory workflows. The instruments still use the Pharma Test MonoShaft design and support staggered stirrer start for manual operation.

PTWS 1230 is equipped with 12 testing positions, allowing for simultaneous dissolution testing across a large number of samples, for example in Biowaiver applications. Additionally, it features two smaller vessels designed to accommodate standard or blank solutions, enhancing the versatility of the instrument in various laboratory scenarios.

PTWS D630 stands out with its innovative dual drive system, offering independent stirrer speed control for both the front and back rows of stirrers and tool sets. This feature provides greater flexibility in test setups and ensures precise dissolution conditions tailored to specific sample requirements.

Instrument Head and Display Design

The PTWS 1230 and PTWS D630 instrument heads feature a robust housing constructed from powder-coated stainless steel, ensuring exceptional durability and ease of cleaning. Integrated into the head is a 7-inch touch display, protected by a solid glass plate. This design not only offers a sleek appearance but also provides reliable protection for the display in demanding laboratory environments.

Optional Instrument Add-Ons

The instruments can be equipped with a variety of installation options:

EPE Automated Sampling System

This system enables automated and precise sample collection throughout the dissolution test. The sampling probes are automatically moved into the vessels during the sampling intervals.

ITM Vessel Media Temperature Monitoring System

By monitoring vessel media temperatures at each sampling event, this system ensures that temperature conditions remain within required specifications during sampling and prior to the start of the test.

TM and TMA Tablet Drop Magazines

The manual or automated tablet drop magazines ensure the simultaneous drop of all samples into the vessels at the start of the test.

Heater and Pump Module Design

The pump and heater have been combined into a single external module with a durable, powder-coated stainless steel housing. The heater module’s internal components have undergone significant advances, incorporating a fully self-contained heating system. This innovation removes the need for a control sensor inside the water bath, simplifying maintenance while ensuring precise and reliable temperature control.

In addition, an external temperature probe is provided for monitoring the temperature within the vessels or the water bath. The heating system’s safety is maintained through an array of internal temperature sensors positioned at both the inlet and outlet of the heater, as well as a resettable thermal cutoff switch.

Instrument Base and Water Bath Enhancements

The water bath has been completely redesigned to enhance stability and durability. A newly developed quick-connector system ensures secure, leak-free attachment of the heater module to the water bath. In addition, the tubing has been upgraded with a larger internal diameter, enabling significantly improved water circulation. As a result, the flow rate of the new instruments is now double that of previous models, eliminating the need for a water diffuser inside the bath.

The water bath is designed for convenient emptying and efficient cleaning. The tap connection has been enhanced for increased stability and repositioned to optimize drainage, facilitating more thorough removal of water. Additionally, both the cover and the water bath are removable, allowing for detailed and intensive cleaning when required.

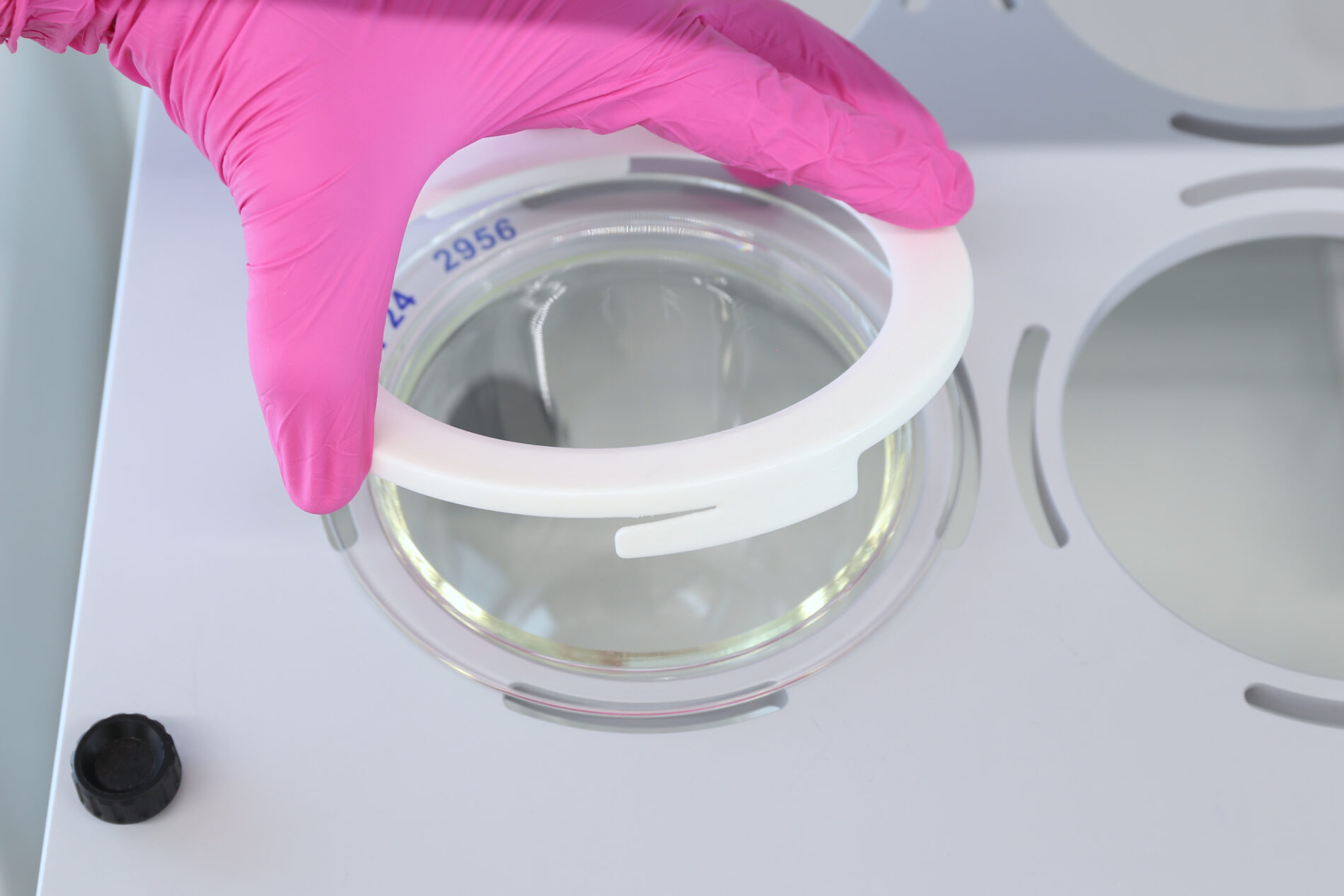

The water bath cover is constructed from Aluminum, offering dimensional stability. Dissolution vessels are inserted into rings fixed to the water bath cover and secured using centering rings equipped with a 3-way bayonet catch mechanism.

Cleaning System

The new instruments are compatible with the popular cleaning system for tubing lines and the EPE automated sampling system. This cleaning system includes a plastic beaker designed to hold cleaning solution and magnetic holders, which can be securely affixed to the underside of the TM tablet drop magazine. In this configuration, the probes of the EPE automated sampling system can be positioned within the beakers, enabling efficient flushing and cleaning of the system.

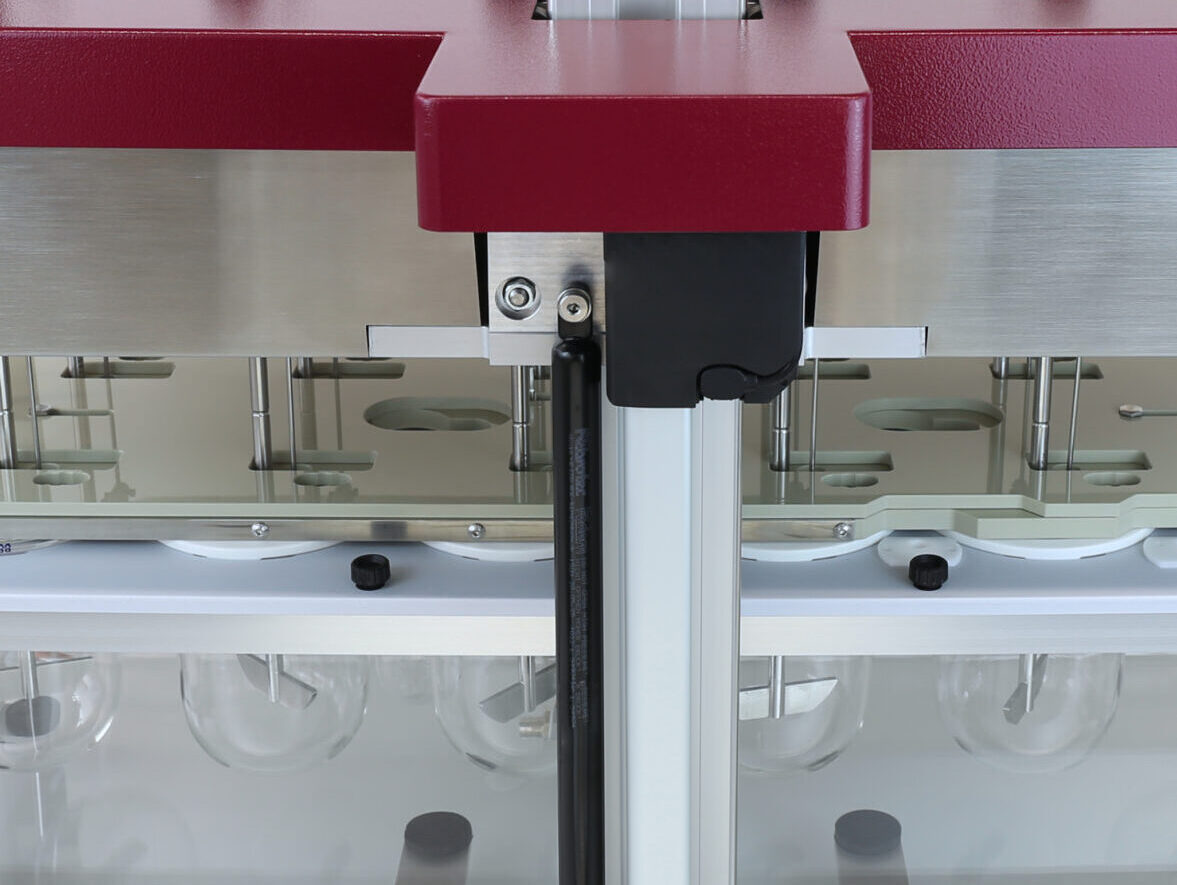

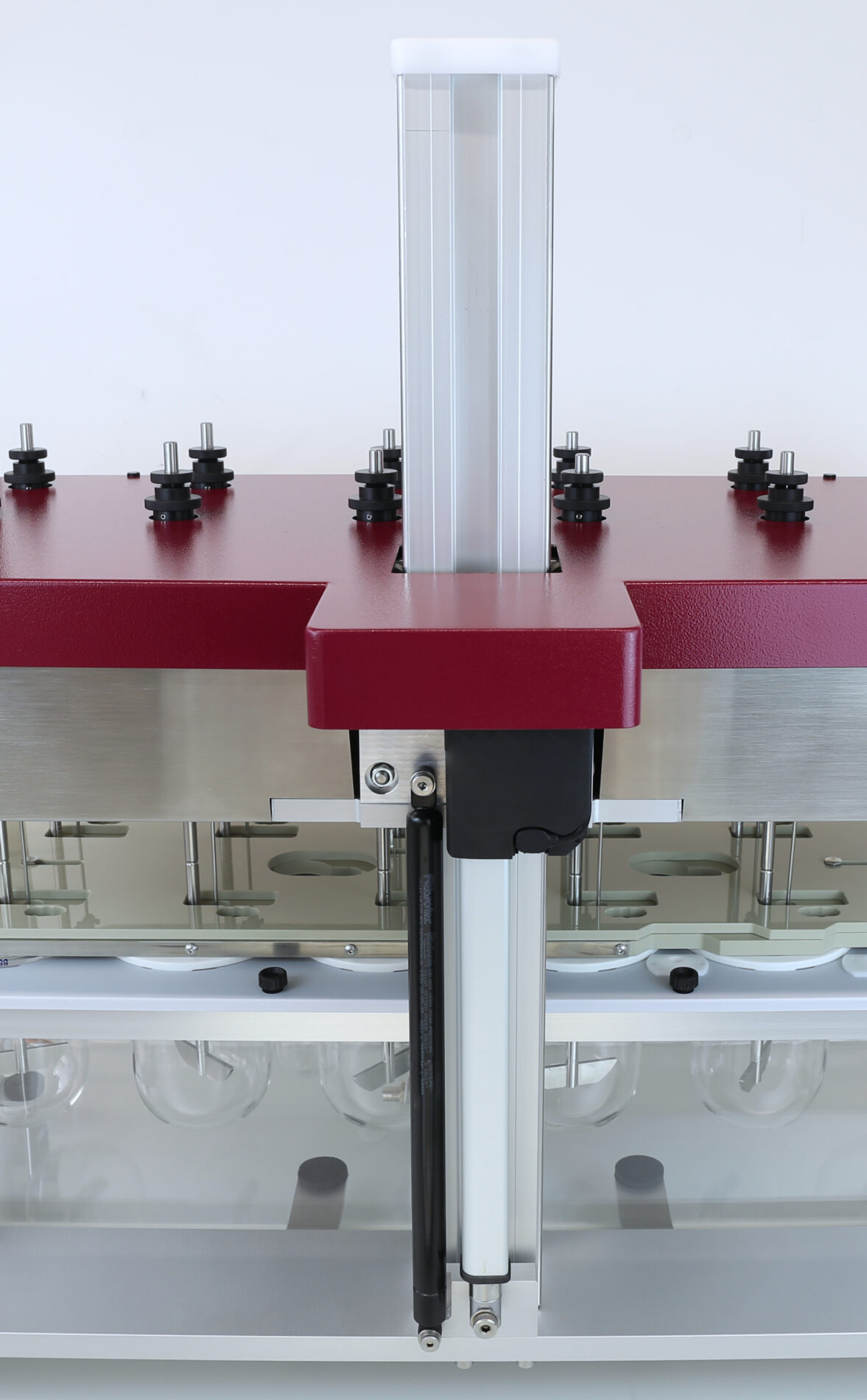

Re-Engineered Electronic Lifter System

The PTWS 1230 and PTWS D630 instruments are equipped with a re-engineered electronic lifter design. This system consists of a rigid, stationary lift column fitted with bearings to support the instrument head. Movement of the instrument head is managed by a linear actuator, which lifts the head, aided by a gas pressure spring. When lowering, the linear actuator operates without force, allowing the head to descend gently under its own weight, counterbalanced by the gas pressure spring. The positioning of the head is still controlled electronically. This design minimizes the risk of damage from obstructions between the instrument head and the water bath.

Both instruments offer the capability to program up to 16 working positions. For models equipped with the EPE automated sampling system, up to 16 sampling positions can also be set, including a dedicated position for cleaning.

Related Products

Related Articles

-

Introducing New Next-Generation 8-Station Tablet Dissolution Testing Instrument PTWS 830

-

On/Offline Dissolution System: Amazing Flexibility Yet Accurate Results either Way

-

New Automated Sampling Manifold Optimized for Manual Sampling for PTWS 1420

-

Media Preparation System PT-DDS4 Now Also Available with Integrated Network Connection

-

Highlights and Impressions at analytica 2024 in Munich from 9-12 April 2024