PTG-NIR

The Power Couple for Powder Flow Analysis and Beyond.

PTG-NIR

Powder Analysis System

The PTG-NIR automatic powder and granule analysis system combines the Pharma Test PTG-S5 powder flow testing instrument with an integrated J&M TIDAS L NIR diode array spectrometer. The system is controlled by the powerful TIDASDAQ3 software including a customized script for the PTG-NIR. The system is ideal to examine the flow characteristics of a powder or granule. This combination is ideal for simultaneous detection of chemical, physical and morphological information. This information is describing the flow behaviors of a powder or granule. Other forms of solids are possible to be tested too. All the results are presented in a single report generated by the included TIDASDAQ3 software.

Construction of the System

The automated PTG-S5 stand-alone powder characterization system is used to measure the flow behavior of granules and powders in compliance with the EP <2.9.36> and USP <1174> Pharmacopoeia. In addition the instrument is also compliant to the ISO 4324 and DIN EN 12047 standards. It features an integrated balance and a built-in printer for a compact foot print. The GMP compliant all stainless steel finish is easy to clean and maintain.

The J&M TIDAS L NIR diode array spectrometer is built-into a separate stainless steel housing from which the fiber optic cable is directly connected to the PTG-S5 instrument. This combination is the PTG-NIR. The NIR measurement accessory greatly expands the application range of the standard PTG-S5 instrument.

Expanded Range of Application

The PTG-NIR is equipped with a J&M NIR diode array spectrometer. A fiber optic probe is swiveled in just below the transparent glass powder dish of the PTG-S5 instrument. The NIR measurement is made by shining the light through the probe window and the glass powder dish, directly into the powder cone that forms on the powder dish. The light penetrates the powder cone enough to provide reproducible spectral results.

By adding the NIR spectrometer the range of application is expanded for the additional analysis of:

- Moisture content

- API concentration

- Qualitative “finger printing” of powder content

- Homogeneity of blended components

Blends of non-active materials can also be analyzed. The system can also shed light on the distribution of an API within a powder blend. It is possible to develop methods to give indications for content uniformity.

Operating Principle of the PTG-S5 Powder Flow Analyzer

The PTG-S5 is widely used to compare batches of powders perhaps supplied by the same manufacturer over a period of time or for similar materials provides by different suppliers. The flow characteristics can be easily and quickly determined as a QC tool for inter- batch reproducibility, as this may have a distinct bearing on the ease of production especially if powders are capable of agglomeration and cohesion over time.

A conical funnel, which can be equipped with different pouring nozzles, takes the sample to be tested. A built-in analytical Sartorius balance cell takes the product collecting dish. The PTG-ER electrical stirrer may be used for powders, which do not flow well. Most pharmaceutical material contains such a high amount of fine particles that it will not start to flow without assistance.

Enter product information using the alphanumeric keyboard of the instrument. The method parameters are automatically transmitted to the TIDASDAQ3 software. Select the test program you want to use:

- Flow time

- Cone angle

- Volume

- Flow-chart

- Density

- Flowability

Then start the test. Depending on the powder the PTG-ER stirrer may be used. When the test is started the funnel is opened and two IR sensors detect the powder flow, this will start the timer to measure the flow time and to record the flow chart. The product itself is collected on a 100mm diameter dish and forms a cone. Once the powder flow stops, the funnel is closed and the movable measuring arm which holds the two infra-red sensors starts to measure the height of the cone up to the tip. Since the surface of the collecting dish is completely filled, the cone angle can be calculated and displayed.

The test should be repeated (in accordance to the ISO 4324 five times) and the deviation of results should not exceed 5%. The test results are displayed at the LCD display of the PTG-S5 and the TIDASDAQ3 software. Using the built-in thermal printer a test report and powder flow-chart will be printed including descriptive information of the product. Furthermore a PDF report is generated by TIDASDAQ3.

To measure the flowability as per EP <2.9.36> and USP <1174> Pharmacopoeia the test is automatically stopped as soon as 100mg of sample have been collected inside a suitable plastic beaker. In addition to the flowability factor (100mg/t) the powder flow chart can be printed.

The standard instrument comes with all attachments to measure flow-time, cone angle and flowability in compliance to the current EP/USP Pharmacopoeia. Different pouring nozzles from 4 – 10 mm can be used to test the product. A stirrer can be used to force non-flowing product through the selected pouring nozzle.

The PTG-S5 powder testing system includes a built-in analytical Sartorius balance cell, which extends the instrument use to test powder flowability, density and volume. Additionally, a graph can be plotted on the built-in printer showing the flow behavior of the sample under test. Using the conical stainless steel funnel as described in the current EP/USP monograph and use the changeable nozzles of 10, 15 and 25mm, the cone angle can also be tested. If smaller diameter nozzles are to be used, an adapter ring which allows the use of pouring nozzles from 4 to 10mm is available.

Up to 10 tests can be performed and used to calculate statistics including mean values of all selected test parameters. The data and results are displayed on the LC-display, presented as hard copy on the built-in printer and transmitted via RS-232 interface to the TIDASDAQ3 data acquisition software.

TIDAS L NIR – The Result of 30 Years of Experience in Fiber Optics

Near-infrared (NIR) spectroscopy is a spectroscopic method that uses the nearinfrared region of the electromagnetic spectrum (from about 700 nm to 2500 nm). Applications include pharmaceutical, food and agrochemical quality control, atmospheric chemistry, and combustion research.

Near-infrared spectroscopy is based on molecular overtone and combination vibrations. As a result, the molar absorptivity in the near-IR region is typically quite small. One advantage is that NIR can typically penetrate much farther into a sample than mid infrared radiation. Near-infrared spectroscopy is, therefore, not a particularly sensitive technique, but it is very useful for probing bulk material with little or no sample preparation.

The TIDAS L NIR is a diode array spectrometer. This technology is much faster compared to common scanning spectrophotometers. Instead of of the sequential scanning technique, the full spectrum is immediately detected and multiple wavelenghts may be examined at the same time. This way even fast spectral changes can be detected by the diode array spectrometer. The TIDAS L NIR provides excellent signal to noise ratio to detect even weak signals.

The use of certified optical fibres in combination with optimised measuring cells allows the achievement of reliable measurement results.

Typically the gratings and mechanical parts of scanning spectrophotometers are prone to misalignment and need frequent calibration. The TIDAS L NIR contains no moving parts or gratings, greatly enhancing the systems reliability and long term stability.

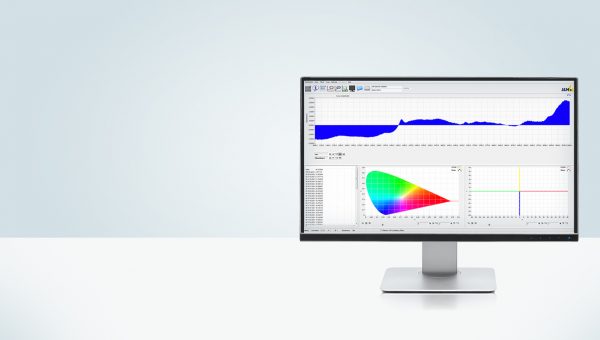

Powering the System is the TIDASDAQ3 PC Software

The PTG-NIR system incldes the powerful TIDASDAQ3 software package including a script customized for the PTG-NIR system. Results from both the PTG-S5 and the TIDAS L NIR are stored and displayed by the software. The script makes it easy for the user to work with the system without requiring a deeper understanding of spectrophotometric theory or chemometrics. Quick access buttons make it easy to perform routine analysis once the method has been developed. For advanced users the full functionaly of TIDASDAQ3 remains accessible. The software is fully 21 CFR Part 11 compliant, including an audit trail and multiple user levels.

Features

- Fully USP <1174>, EP <2.9.36> and ISO 4324 (12/83) compliant

- Measure flow-time, cone angle and flowability

- Gather chemical, physical and morphological information

- Included white standard for reference scan, integrated shutter for dark current measurement

- Includes TIDASDAQ3 software with customized script

- Integrated clear view dust protection hood for the powder test area

Advantages

- Measure the flow behavior of powders and granules to reduce process costs and maintain quality and consistency of the final product

- Gather chemical, physical and morphological information by using the integrated NIR spectrometer

- Fast diode array NIR spectrometer provides immediate full spectra and contains no moving parts

- Excellent S/N ratio to detect weak signals

- IQ/OQ documents included free of charge

Technical Data PTG-S5

| Parameter | Specifications |

|---|---|

| Display | High resolution color LCD, backlit |

| Data Entry | Touch screen, USB keyboard optional |

| Instrument Firmware Compliance | 21 CFR Part 11 |

| Firmware Features | User management, method management, result database, audit trail |

| Cone Volume | Approx. 450ml |

| Cone Material | Stainless Steel |

| Range for Cone Angle Test | 25.0° to more than 65.0° |

| Range for Flowability Test | 0.1 sec. to 999 sec. - mass: 100g |

| Range for Flow Time Test | 0.1 sec. to 999 sec. |

| Range for Cone Density | 0.000g/ml-1 to 6.0g/ml-1 |

| Range for Cone Weight | 1mg to 325g |

| Range for Cone Volume | 0.1ml to 275ml |

| Interfaces | USB, LAN |

| Printer | Built-in thermal printer, optional use of USB or LAN printers |

| Instrument Housing | Stainless steel to meet GLP requirements |

| Instrument Dimensions | Approx. 50cm x 55cm x 90cm (width x depth x height) |

| Packaging Dimensions | Approx. 90cm x 67cm x 80cm (width x depth x height) |

| Net / Gross Weight | Approx. 35 / 50 kg |

| Certification | All components certified to USP / EP requirements |

| CE / EMC Certification | All CE / EMC Certification provided |

| Validation | All IQ & OQ documents included |

We reserve the right to make technical changes without any prior notice.

Technical Data TIDAS L 900 NIR

| Parameter | Specifications |

|---|---|

| Wavelength Range | 1100 - 2100 nm |

| Spectral Resolution | < 6 nm FWHM |

| Wavelength Accuracy | ± 0.5 nm |

| Photometric Accuracy | ± 10 mAU |

| Wavelength Reproducibility | < 0.1 nm |

| Signal-to-Noise Ratio | 250 : 1 |

| Included Light Source | 7.5W Halogen |

| Number of Diodes | 256 |

| Bench Space Requirements | Approx. 47 x 37 cm |

| Packaging Dimensions | Approx. 80 x 60 x 60 cm (W x D x H) |

| Weight | Approx. 12 kg net weight, 18 kg gross weight |

| Power Supply | 85 – 265 VAC / 47 – 63 Hz |

| Interface | TCP/IP 10/100/100 Mbit/s |

| Optical Fiber Connection | SMA 905 |

| Illumination | SMA 905 |

| Digital I/O | Standard: 2 x IN / 2 x OUT |

| A/D Converter | 16 Bit |

| Integrated Computer | 10.4” touchscreen, Windows 10, 64GB SSD |

| Supply Scope | TIDASDAQ 3 software, power supply, keyboard, mouse, manual |

We reserve the right to make technical changes without any prior notice.

Included in the Standard Scope of Supply

The PTG-NIR comes ready to use with the following system components and standard scope of supply:

- PTG-S5 powder flow analyzer

- TIDAS L NIR spectrometer

- TIDASDAQ3 PC software package

- Fiber optic cables and customized probe

- White reference standard

- Pouring nozzles size 6, 8, 10, 15, 25mm

- 600ml beaker

- 30° angle calibration cone

- Comprehensive documentation folder including:

- User manual

- QC/DQ testing certificate

- IQ documentation

- OQ documentation

- Conformity Declaration

- CE/EMC Declaration

- Instrument logbook