DFC-820SP including PTWS 820D Dissolution Bath

Offline automated dissolution system with 8 position bath.

DFC-820SP including PTWS 820D Dissolution Bath

DFC-820SP

Semi-Automated Dissolution Test System

The offline DFC systems include a fraction collector or an auto sampler which will collect the sampled dissolution media. The semi-automated DFC-820SP system is composed of a PTWS 820D staggered stirrer start dissolution bath with built-in individual vessel centering, full tubing installation in PTFE including either in-situ sampling probes or the EPE-820 auto sampling system, a PT-SP8 syringe pump, and a PTFC-2/8SP fraction collector. In this configuration the sampling probes are either always immersed into the media (in-situ) or removed after sampling (EPE-820 system). Both procedures are widely used.

Semi Automated Tablet Dissolution Testing

Semi-automated in this case means auto sampling for a dissolution test instrument at pre-programmed times. Automating this step alone eases the dissolution job a lot. After all tablets have been dropped, the dissolution test proceeds automatically and all samples are simultaneously removed from each connected vessel.

The sample is delivered into a connected fraction collector by a peristaltic-, or the PT-SP syringe pump. These systems do not require any external PC software to control them (the WinDiss ARGUS dissolution software package can be used optionally).

Sampling information is entered directly at the connected PTWS 120D/S dissolution testing instrument.All Pharma Test tablet dissolution test instruments can be upgraded with a pump and PTFC-2/8 fraction collector or DSR-M sampling robot.

Automated Sampling

The perception of automation in dissolution testing differs greatly from user to user. The most labor intensive stage is taking samples at the specified time periods as found in the company SOP (Standard Operating Procedure).

This involves the removal of 6 samples according to the USP/EP and most other Pharmacopoeia, there is often a requirement for a fast or parallel start in most cases so that accurately timed sampling may be achieved.

At this point the operator must also consider either replacing the collected samples volumes in the dissolution vessels or keeping an accurate record of the volumes taken from each vessel so as to be able to calculate the true concentrations of subsequent samples.

The pumps available are either peristaltic, piston pumps, or syringe pumps. The PT-SP syringe pump as well as the CAT valve-less piston pump will give first class accuracy in terms of volume removed and refilling from and back to the system when samples are taken.

Although the quality of the peristaltic pumps available today has vastly improved, it must be stressed that the peristaltic pump is still working with flexible tubing and should be qualified at the start of each determination to make sure that the flow rates are identical for each channel and that the tubing itself is in overall good condition. A good tip for long tubing life is to always release the pressure rollers from the tubing either overnight or whenever the system is left for extended periods of time and not in use.

PT-SP Multi Syringe Pumps

The PT-SP multi-syringe pump is designed specifically for parallel sample withdrawal and dosage of media from a dissolution bath into open vials inside a fraction collector. It is equipped with up to 8 replaceable 10ml high precision glass syringes. Each syringe is connected to a 3-way pinch valve for media flow control. The drive of the syringes is carried out simultaneously by a stepper motor. All syringes are rigidly connected to the common sturdy drive bar.

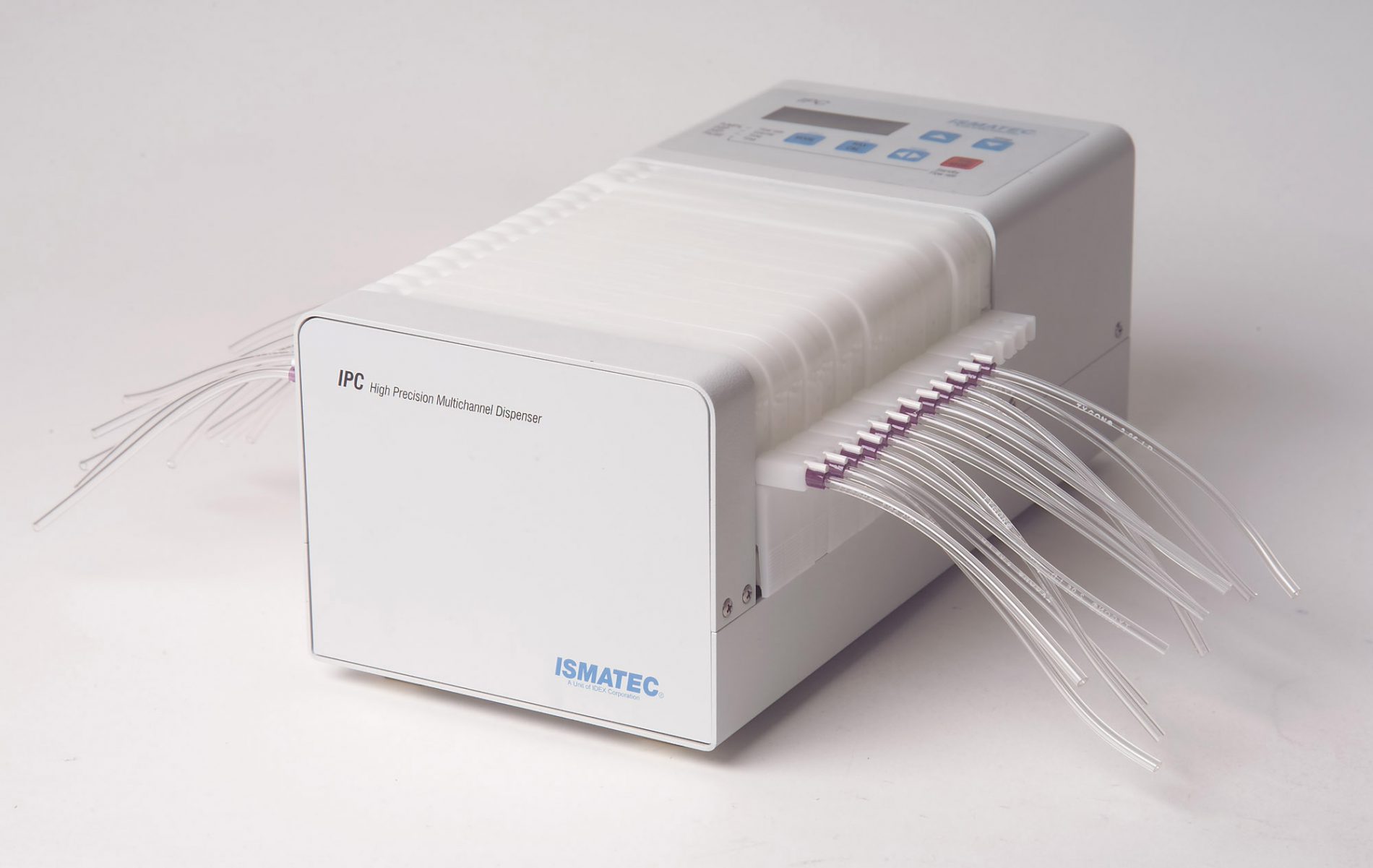

Peristaltic Pumps

The Ismatec® IPC 8, IPC 16 and IPC 24 series of pumps offers a reasonable cost solution for prolonged use. With the PTFC-2/8 fraction collector and their reverse liquid flow feature, the DFC systems provide the necessary control for sample transfer using this type of pump for standard off line systems.

CAT Valve Less Piston Pumps

The CAT multiple piston pump units offer a more accurate solution to sample removal and transfer. Exact volumes may be transferred from the sample vessels to a fraction collector such as the PTFC-2/8. In this way, as vessel refilling is not used, exact volumes of sample removal can be recorded for subsequent concentration calculations.

This system offers a more secure sampling method for non-closed loop or offline systems where the volume removed is calculated from an apparent flow rate over a fixed time period (as with peristaltic pumps).

This system is not dependent on pump tubing quality and is also a good alternative when active materials are known to absorb on tubing materials such as Tygon or Silicone. The CAT pump is available with 6, 8, 12 and 24 individual pump heads, also for auto media refilling.

Operation Principle

As soon as the samples have been inserted, the system will start its automated operation. The sampling times have been programmed via the touch screen of the PTWS 820D dissolution bath and are saved as a specific method for subsequent tests.

After the start of test a command is sent from the dissolution bath to the PTFC-2/8 fraction collector and from there to the connected pump to start a sampling sequence. The EPE-820 moves the sampling tubes and filter tips into the media to the selected sampling position.

The pump will be started to fill up and pre-flush the tubing. When all tubing is filled-up, the samples are collected into vials inside the collector dish of the PTFC-2/8. Depending on the system configuration, after dosing the volume will be refilled and the EPE-820 will move back out of the dissolution vessels.

At the end of a cycle all tubing is emptied. The system is waiting for the next sampling time. All vials are covered during the test; the vial dish can be easily removed. Also special dishes are available for HPLC vials.

This involves the removal of 6 samples according to the USP/EP and most other Pharmacopoeia, there is often a requirement for a fast or parallel start in most cases so that accurately timed sampling may be achieved.

At this point the operator must also consider either replacing the collected samples volumes in the dissolution vessels or keeping an accurate record of the volumes taken from each vessel so as to be able to calculate the true concentrations of subsequent samples.

The pumps available are either peristaltic, piston pumps, or syringe pumps. The PT-SP syringe pump as well as the CAT valve-less piston pump will give first class accuracy in terms of volume removed and refilling from and back to the system when samples are taken.

Features

- Automated temperature check and log at all sampling times

- Fully USP <711/724> and EP <2.9.3/4> compliant

- 8 stirred positions

- System composed of PTWS 820D dissolution bath, PTFC-2/8SP fraction collector and PT-SP8 syringe pump. Alternatively Ismatec peristaltic pumps or CAT piston pumps may be used

- Automated withdrawal of samples at specified times via movable probes (EPE-820 required)

- Media temperature monitoring when sampling (ITM-820 required)

- Parallel Tablet Drop (TM-820 or TMA-820 required)

- Printed test report (PT-RP80 required)

- Automated media refilling

Advantages

- The system automates the taking of samples, the most labor intensive stage of a dissolution test

- Automated sampling eliminates human errors, as equal sampling times and standardized solvent transport offer high reproducibility

- Excellent reproducibility of sampling volumes and times

- Offers unattended operation after start of dissolution run

- Pharma Test offers full system responsibility

Technical Specifications PTWS 820D

| Parameter | Specification |

| Display | 6”, 320×240 pixel color LCD, illuminated |

| Data Entry | Resistive touch screen |

| Acoustic Signal | Acoustic signal for operator information at programmable intervals |

| Timer | Programmable sampling times, wake-up and sleeping mode, operation time information and timer count-down mode |

| Stirrer Position | 8 programmable stirrer immersion positions (paddle over disk, transdermal cylinder etc.) |

| Testing Method Descriptions | Unlimited number of different test descriptions can be stored on SD card |

| User Access Control | Multiple level access control |

| OQ, PQ control | Programmable time periods to remind on QO or PQ testing |

| Printer | External PT-RP80 report printer |

| Number of Stirred Vessels | 8 (4 by 2 or 2 by 4 arrangement) |

| Standard Vessels | 1 liter USP/EP Borosilicate glass vessel, each individually coded |

| Speed Control | 25 – 250 RPM |

| Speed Accuracy | ±2% of set speed, typically < 1% |

| Stirrer Shaft Wobble | Better than 0.2 mm total run out |

| System Tools | MonoShaft™ stirrer design, USP/EP apparatus 1, 2, 5, 6 tool adapter, cream cell, transdermal patch tools, each tool and vessel individually coded |

| Heating System | Pump for water circulation; 1400W heater for fast heating up |

| Heater Range | 25 – 45°C |

| Heater Accuracy | ± 0.2°C inside the water bath |

| Heat Up Process | Energy saving, programmable “wake up” heater function and “sleep mode” |

| Water Circulation | Water circulated from external heating system through special diffuser inside the water bath |

| Vibration Elimination | External heating system, spring loaded pump assembly |

| Calibration | Built-in calibration procedures for speed, temperature control, OQ/PQ interval programmable including alarm indicator |

| Bench Space Requirement | 450 x 750 mm (2 by 4) or 750 x 450 mm (4 by 2) |

We reserve the right to make technical changes without any prior notice.

For more information about the pumps and the system have a look at our brochures.

Included in the Standard Scope of Supply

- TM-820 manual tablet drop magazine

- EPE-820 automated sampling system

- PTFE tubing installation for offline sampling

- PTFC-2/8SP fraction collector (sampling only)

- PT-SP8 syringe pump

- One set of stainless steel paddles

- One set of 1000ml Borosilicate glass vessels

- One set of depth adjustment balls

- One bottle of ALGEX water preservative

- Comprehensive documentation folder including:

- User manual

- DQ/QC instrument compliance test certificate

- IQ documentation

- OQ documentation

- Instrument logbook

- Compliance Certificates for vessels and stirring tools

Options

- Cleaning system for tubing lines with magnetic holders

- Amber colored vessels for UV sensitive test materials

- ITM-820 individual media temperature monitoring system

- TMA-820 motorized tablet drop magazine

- PT-RP80 serial report printer

- Additional linked PT-SP media refilling syringe pump or E-VEN pinch valve system used at the PTFC-2/8 fraction collector for automated media refilling and 16 or 24 channel peristaltic pump

- Customized collector dishes for HPLC or other vials

- Full range of MonoShaft™ stirring tools available

- Different pore size filter tips

- Full range of certified validation tools available