PTWS 820-MA

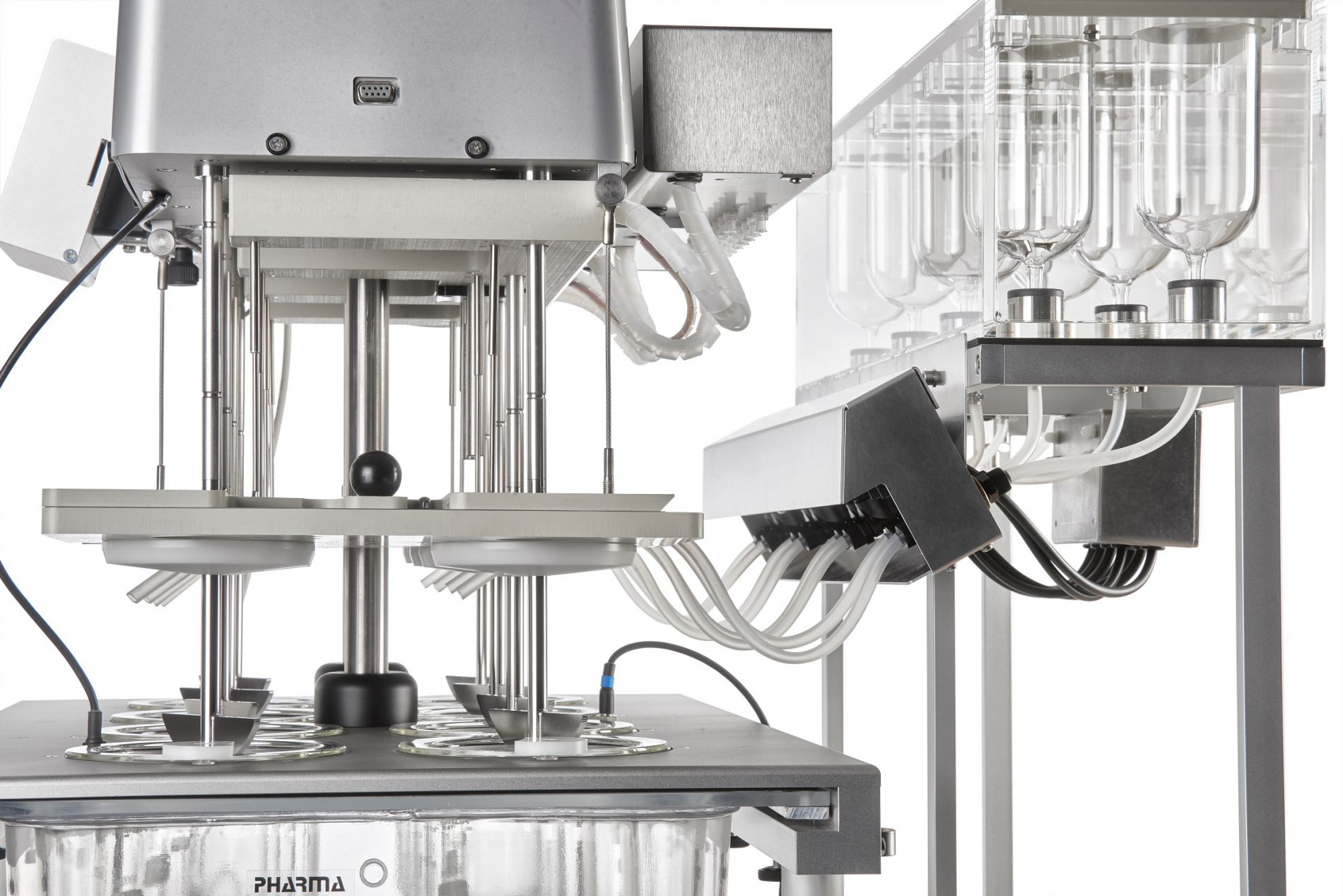

8-Position USP/EP Tablet Dissolution Testing Instrument with Media Addition Station

PTWS 820-MA

8-Position USP/EP Tablet Dissolution Testing Instrument with Media Addition Station

The Pharma Test media addition station PTWS 820-MA together with the PTWS 820D tablet dissolution testing instrument can be used to perform the automated media half change for delayed release dosage forms. The operation is performing according to the requirements from USP <711>, EP <2.9.3> and CP <931> for delayed release dosage forms (in CP, enteric coated dosage forms). The test will start with 750ml of 0.1N HCl. After 2 hours, 250ml of concentrated, pre-heated buffer solution will be dosed quickly into the dissolution vessels. The pH will change to 6.8 and the dosage form should then start to dissolve.

Fully Compliant

Pharma Test has designed the automated media change station PTWS 820-MA which can pre-heat and dose 250ml of concentrated buffer very quickly and simultaneously to the vessels of the PTWS 820D. A heated waterbath is used to pre-heat the concentrated buffer solutions in individual glass vessels. The correct temperature is important, as the amount of liquid added to the vessel is about 250ml. The temperature in the test vessels has to stay within the USP range of 37+/-0.5°C at all times. Therefore the added media should be heated up to 37 °C as well, as the addition of cold media would signifcantly affect the temperature in the test vessels. This way the test can continue immediately as required by USP, CP and EP. It is also possible to operate the whole system via the WinDiss ARGUS dissolution software.

Features

- Automated temperature check and log at all sampling times

- Fully compliant with USP <711>, EP <2.9.3> and CP <931> recommendations for delayed release testing

- For automated operation of USP, EP and CP dissolution test for delayed release (CP enteric-coated preparations) dosage forms

- Unattended operation for the media change. Saves time. Customers can start the dissolution test in the evening. Not necessary to wait for the 2h.

- Very fast buffer adding (less than 30sec for 250ml). Corresponds to a pump flowrate of 500ml/min. According to USP <711> and EP 2.9.3 the test must be “proceeded immediately” after the 2h in 0,1N HCl. “all test times stated are observed within a tolerance of +/-2%”.

- Includes an additional heating system which will preheat the buffer. The concentrated buffer (6x250ml) must be preheated to keep in the USP Tolreance of 37 +/-0.5°C

- No temperature change in the dissolution vessel as the preheated buffer will be transferred very quickly.

- 6 vessels are simultaneously filled with the concentrated buffer. No time gap.

- No Pumps are used

- Gravity and a valve system are used for the fast media dosing

- The valves will automatically open after 2h

- The system can be operated by WinDiss ARGUS dissolution PC software

Advantages

- Very fast buffer adding which corresponds to a pump flowrate of 500ml/min

- According to USP <711> and EP 2.9.3 the test must be “proceeded immediately” after the 2h in 0,1N HCl

- Includes an additional heating system which will preheat the buffer in the USP Tolerance of 37 +/-0.5°C

- No temperature change in the dissolution vessel

- Unattended operation for the media change

Technical Specifications

| Parameter | Specification |

| Number Vessels | 8 |

| Standard Vessels | 250 milliliter USP/EP Borosilicate glass vessel, each individually coded |

| Vessel Covers | Ultra-low evaporation design (< 0.7% within 24h) |

| Heating System | Pump for water circulation and 1500W heater for fast heating up (230/240V units only) |

| Heater Range | 25-45°C |

| Heater Accuracy | ± 0.2°C inside the water bath |

| Water Circulation | Water circulated from external heating system through special diffuser inside the water bath |

| Vibration Elimination | External heating system, spring loaded pump assembly |

| Instrument Dimensions | Bath: approx. 60cm x 25cm x 64cm (width x depth x height) Heater: approx. 26cm x 37cm x 21cm (width x depth x height) |

| Net Weight | Approx. 12kg waterbath, 5kg heater |

| Certification | All components certified to USP / EP requirements |

| CE / EMC Certification | All CE / EMC Certification provided |

| Validation | All IQ & OQ documents included |

We reserve the right to make technical changes without any prior notice.

Included in the Standard Scope of Supply

- Plexiglass water bath

- One set of 250ml Borosilicate glass vessels

- Comprehensive documentation folder including:

- User manual

- DQ/QC instrument compliance test certificate

- IQ documentation

- OQ documentation

- Instrument logbook